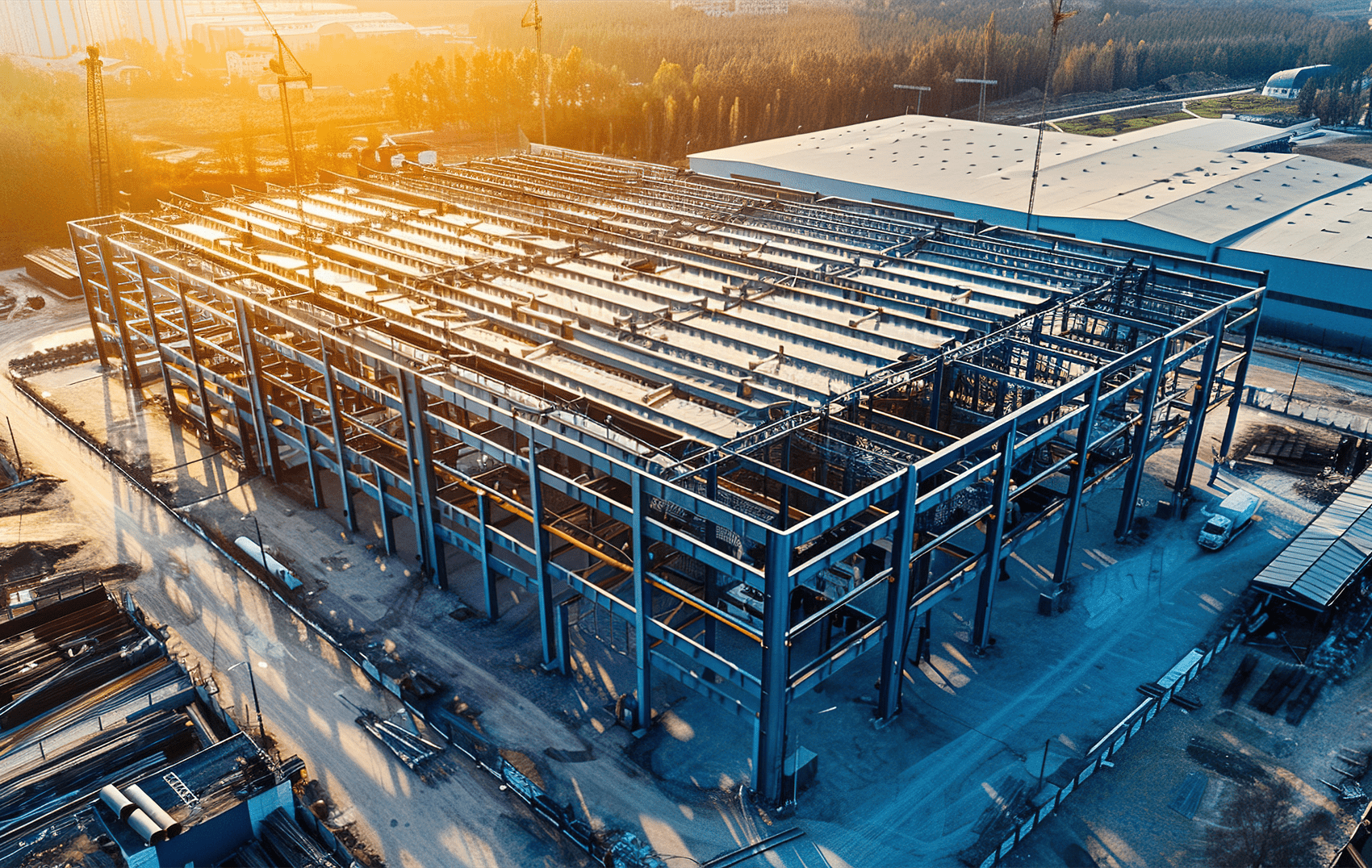

Pre-Engineered Buildings (PEB) are innovative structures designed and manufactured in a factory setting, allowing for rapid and efficient assembly at construction sites. This approach leverages advanced engineering techniques and modern software to create tailored building solutions that meet specific client requirements. PEBs typically consist of steel frameworks, panels, and roofing systems that are prefabricated to precise specifications, ensuring high quality and structural integrity.

One of the key advantages of PEBs is their adaptability; they can be designed for various applications, including warehouses, manufacturing facilities, sports complexes, and retail spaces. The use of high-strength steel enhances the durability of these buildings, enabling them to withstand extreme weather conditions, seismic activity, and other environmental factors. Additionally, PEBs can be customized in terms of size, layout, and appearance, providing architects and developers with the flexibility to create functional and visually appealing structures.