Cold rolled purlins are structural components widely used in the construction of buildings, particularly in the framework of roof systems. Made from high-strength steel, cold rolled purlins are produced through a cold-forming process, which involves shaping steel sheets into the desired profile without the application of heat. This method results in lightweight, yet strong, components that provide excellent load-bearing capabilities.

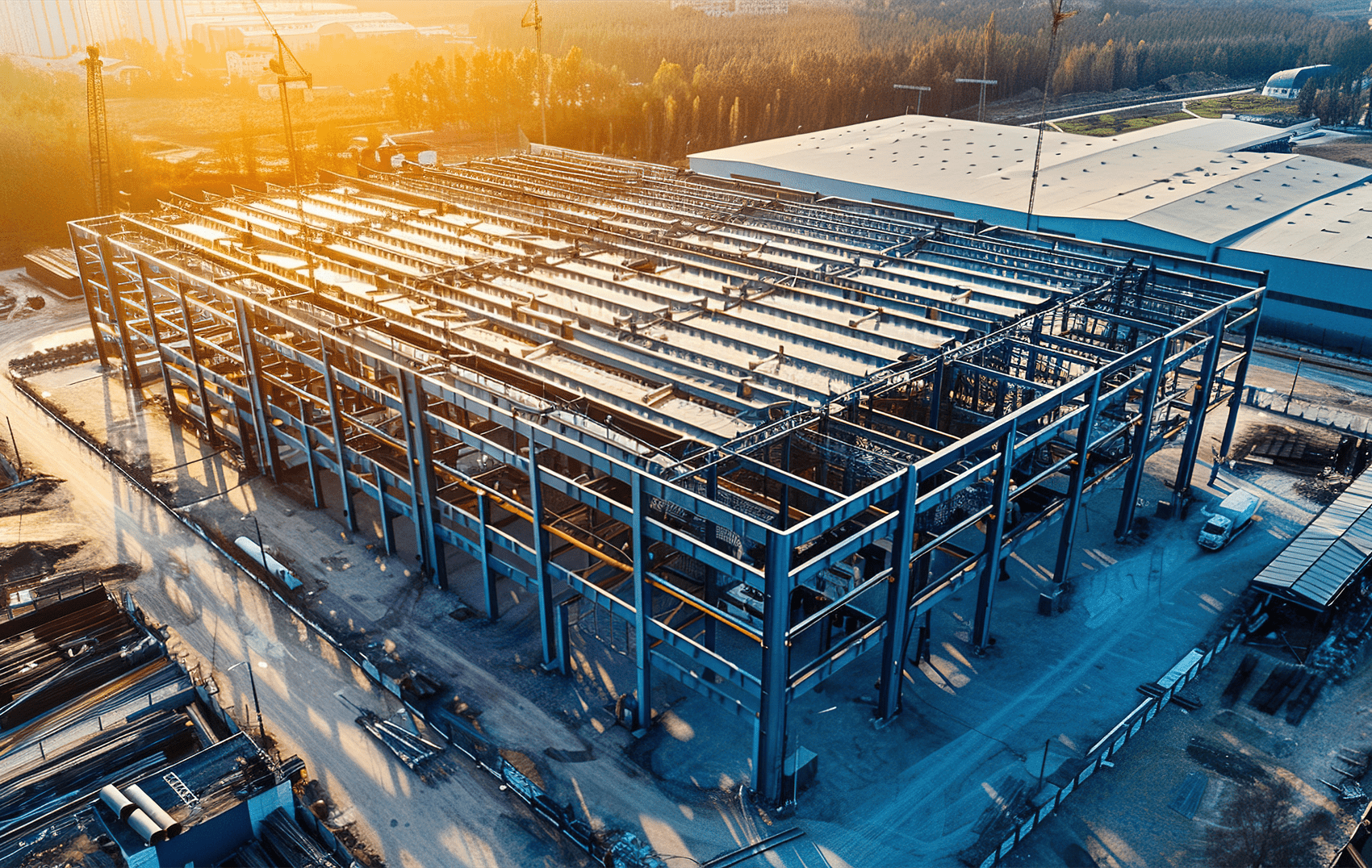

Cold rolled purlins are available in various shapes, such as C, Z, and U sections, allowing for versatility in design and application. Their lightweight nature facilitates easy handling and installation, making them ideal for both commercial and industrial structures. Cold rolled purlins are commonly used in pre-engineered buildings, warehouses, and agricultural facilities, providing support for roof sheeting and enhancing the overall structural integrity of a building.

The manufacturing process for cold rolled purlins ensures high dimensional accuracy and a smooth finish, which improves their performance and aesthetic appeal. Furthermore, these purlins can be customized to meet specific project requirements, making them suitable for various construction applications.